ST. LOUIS, MO The Mississippi Floodwall ORS Pump Station Rehabilitation Project consists of rehabilitation work for the Baden Pump Station, Harlem Emergency Closure Structure, and Mill Creek Pump Station, which is designed to provide system rehabilitation to accommodate a 100 year desired lifecycle while maintaining current operational function.

The project featured removal and replacement of roller gates and appurtenances at the Baden and Mill Creek locations. Roller gate replacements include a provision for water diversion within the structure, structure, actuator refurbishment, new stainless gates, rails, seals and assemblies, as well as structure modifications to accommodate the replacement. Roller gate replacement will occur sequentially to allow no more than one (1) gate to be out of service at a time per location. Emergency plans for stop log installation were created to ensure the integrity of the pump station system in the event of higher than normal river levels during these months. Slide gate rehabilitation are exclusive to the Harlem Emergency Closure Structure. These gates require actuator refurbishment at two locations, as well as seals, blocks, alignment and other modifications at all four gates. In addition, concrete and stop log slides were also rehabilitated at this site. The refurbishment of the Harlem slide gates included the extraction of existing gates to allow access for seal replacements and adjustments. River and stormwater diversion for the concrete and stop log work will be required at the Harlem location along with an emergency action plan for irregular river water levels.

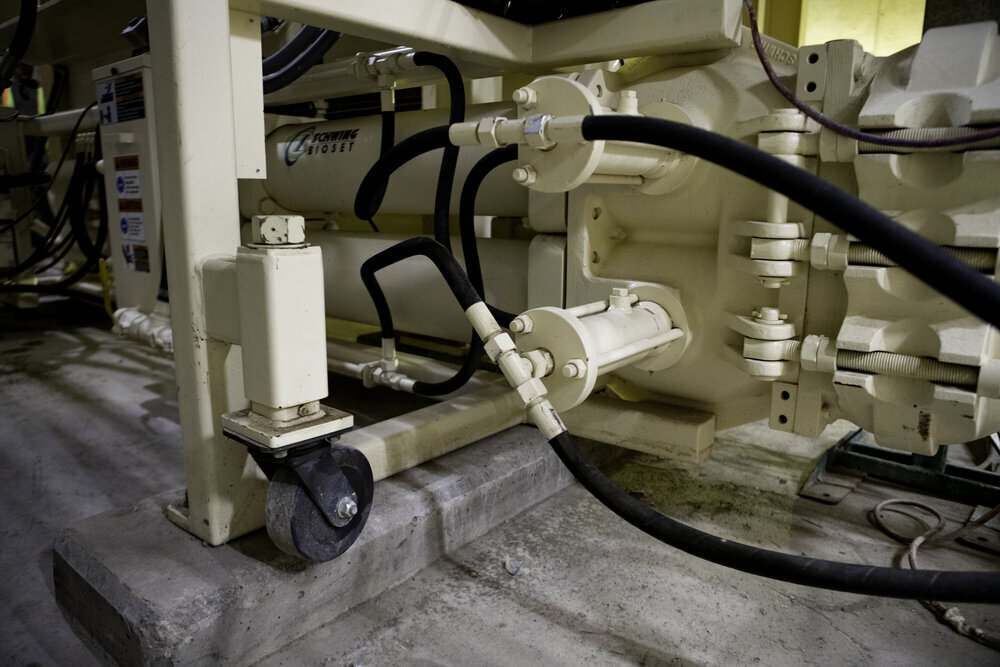

Access to Shutter Gates and upper chamber will be enhanced by the installation of larger opening at the actuator slab elevations. These openings within the existing structural slab were cut between existing beams and dressed with new steel closures, grating and permanent handrail. The new opening will allow MSD for eased future access for maintenance and modifications. Roller Gates within the lower well will require a water diversion system to accommodate fluctuation in river levels. Diversion systems included structural panels that mount to adjacent existing structure with the ability to provide dry working conditions up to RS20 at Baden and RS16 at Millcreek. Work within the diversion structure included the rehabilitation of existing stop log channels, removal and reinstallation of gate rails, and concrete remediation. Hydraulic actuators from the Baden Pump Station and Harlem Closure Structure required refurbishment from the original manufacturer.